Liquid packing equipment plays a vital job in the efficient and correct packaging from the wide selection of liquid goods. Applied throughout industries like foodstuff and beverage, prescription drugs, cosmetics, and chemicals, this equipment signifies that goods are crammed, sealed, and packed promptly, hygienically, with negligible waste. As need for precision and pace will increase, modern day liquid packing gear has grown to become modern-working day, giving enhanced automation, adaptability, and dependability.

At its Main, liquid packing products encompasses numerous integrated programs that truly work with each other to fill, seal, and get ready liquid items for distribution. These programs can involve liquid fillers, capping machines, labelers, and carton sealers. The leading aim would be to shift liquid from the storage tank or reservoir into containers for example bottles, pouches, drums, or Bag-in-Box (BIB) formats with precision and effectiveness.

Diverse sorts of filling mechanisms are utilized in accordance with the viscosity Along with the liquid and also the form of container. Gravity fillers and overflow fillers are perfect for slim, free-flowing liquids like drinking water or juice, when piston Liquid packing equipment and pump fillers are much better suited to thicker, extra viscous substances such as sauces, oils, creams, and gels. Some products takes advantage of flowmeters or weigh scales to make certain precise dosing, that is certainly vital in industries the place product or service regularity is vital.

Modern-day liquid packing devices generally comes with person-helpful digital controls and touchscreens that let operators to change options easily and observe general performance in authentic time. Clear-In-Place (CIP) devices and stainless steel building preserve hygiene standards, notably significant in foods and pharmaceutical apps.

One standout Resolution with this particular subject emerges by suppliers like Flex Pack Service & Materials in Australia. They design and manufacture flexible, semi-computerized and handbook liquid packing equipment customized to distinct generation demands. Their equipment can fill volumes from 0.five a person,000 liters and deal with several different packaging formats, from bottles and casks to massive industrial containers.

The main advantages of working with liquid packing products are lots of: enhanced production pace, decreased labor prices, minimized merchandise wastage, and enhanced packaging consistency. For corporations trying to get to improve operational effectiveness and product or service high quality, purchasing significant-quality liquid packing resources are an excellent and necessary shift.

In summary, liquid packing tools are a cornerstone of modern producing, providing the precision and efficiency necessary to fulfill currently’s competitive industry demands.

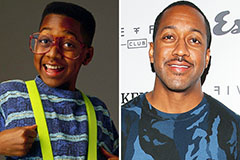

Jaleel White Then & Now!

Jaleel White Then & Now! Ralph Macchio Then & Now!

Ralph Macchio Then & Now! Jurnee Smollett Then & Now!

Jurnee Smollett Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now!